Quality Management

Discover how ISO 9001 and IATF 16949 can help your company grow and compete in demanding markets.

ISO 9001 implementation

In today’s dynamic world, quality standards are essential for success in all sectors – industry, government, construction, healthcare, and more. ISO 9001:2018 is the world’s most widely adopted quality management system, designed to help organizations meet the highest standards of product and service delivery.

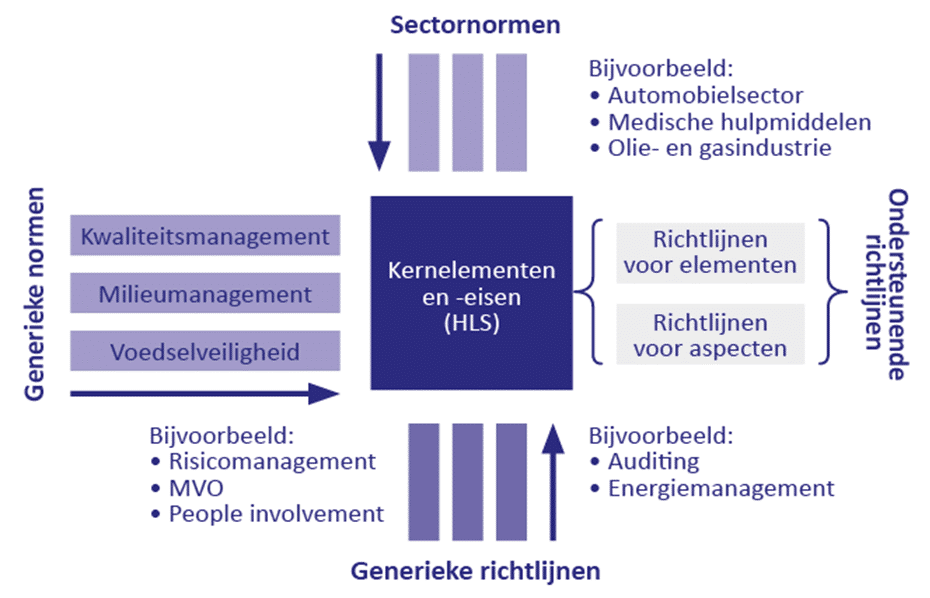

The High Level Structure approach (HLS) involves an approach to the organization and the chain of which it is a part, in contrast to the old standard. Management has a much more emphatic role than before. Because of Symbol’s pragmatic method of implementation, the ISO9001:2018 High Level Structure standard is in line with the entrepreneurial spirit of companies and interacts nicely with ongoing Lean and continuous improvement programs. Symbol sees ISO9001 as a means to provide structure, manage risks and create an improvement culture, rather than as an unwieldy management system that is mainly based on a lot of administration.

Symbol’s Q experts help implement the best-fit quality management system and also make it live within the organization.

ISO 9001 quality management can be divided into three focus areas

ISO 9001 quality management can be divided into three focus areas

Quality Planning - Quality Planning

Quality Planning is a crucial aspect of effective quality management. It focuses on strategically planning how organizations can meet their quality policies.

This includes translating that policy into measurable objectives and specific requirements.

Quality Control - Quality Control

Quality Control focuses on identifying and detecting errors in production processes. This includes thorough inspections and controls applied during production to ensure that only high-quality products reach the following process steps or are delivered to customers

Quality Assurance - Quality Assurance

Quality Assurance is all about prevention. It includes proactive measures to prevent errors in both products and services. This starts as early as the preparation phase of production, where strict controls and procedures are implemented to ensure that the highest quality standards are maintained throughout the process.

IATF 16949 implementation

For companies (Tier-1 & Tier-2) supplying the automotive industry (OEM), it is mandatory to work according to the guidelines of IATF 16949. Symbol’s IATF-certified experts have already helped more than 100 automotive companies implement IATF 16949 and apply Core Tools such as APQP, PPAP, FMEA, MSA, SPC and 8D Problem Solving.

Even outside the automotive sector, more and more companies, particularly in hight tech, are working to the IATF standard. Symbol, for example, has supported many companies in the ASML supply chain to meet increasingly stringent quality requirements.

Want to learn more or train yourself? Symbol specializes in IATF 16949 training, including Core Tools and IATF 16949 Auditor training. Symbol works with accredited IAF 16949 1st/2nd party auditors. Whether you are directly or indirectly involved in IATF 16949 standards, we offer practical and effective training that will help you meet the requirements.

What is the difference between ISO 9001 and IATF 16949?

1. Sectors

ISO 9001

ISO 9001 is a general international standard for quality management. It applies to organizations in a variety of industries, including manufacturing, services, healthcare, education, and more. ISO 9001 is not specific to any one industry.

IATF 16949

IATF 16949 is an industry-specific standard developed specifically for the automotive industry. It is intended for organizations involved in the production and supply of parts and materials to the automotive industry.

2. Scope

ISO 9001

ISO 9001 emphasizes general quality management principles such as customer satisfaction, continuous improvement and process control. It does not require specific technical or product-related requirements.

IATF 16949

IATF 16949 includes all the requirements of ISO 9001 but adds specific requirements relevant to the automotive and semiconductor sectors. These include stringent requirements for product safety, product traceability, risk assessments, and more.

3. Certification

ISO 9001

ISO 9001 certification is used worldwide. Companies can be certified by recognized bodies. Symbol helps companies get ready for certification.

IATF 16949

IATF 16949 certification is mandatory for Tiers in the automotive sector. They can be certified by official bodies. Symbol helps companies prepare for this certification and train the required internal auditors.

DAF Trucks trained in IATF standards

DAF Trucks increased its knowledge of the IATF standard and trained managers in structured auditing using Symbol. More than 30 Supplier Quality Managers were trained in theory and practice, focusing on tools such as FMEA, APQP and PPAP. The trainings have resulted in certified auditors and improved efficiency in identifying supplier deficiencies, greatly improving audit processes at DAF Trucks.

Results:

✅ 30+ managers trained and certified.

✅ Increased audit skills and efficiency.

✅ Integration of proprietary audit tools into training.

SEKISUI S-Lec achieves ISO9001 certification

Successful IATF implementation at Shin-Etsu Silicones Europe

Christenhusz increases customer satisfaction with ISO9001

people certified in Lean Six Sigma

elevated organizations to a higher level

years of lasting impact

Frequently asked questions about quality management

How long does it usually take to obtain ISO 9001 or IATF 16949 certification?

The time required to achieve certification can vary depending on the size and complexity of the organization, as well as its current level of compliance with the standards. It can range from a few months to more than a year.

What steps are involved in the certification process for ISO 9001 or IATF 16949?

The process typically includes an initial assessment of the existing quality management system, identification of areas in need of improvement, implementation of changes, internal audits and finally an external audit by an accredited body.

What training opportunities does Symbol offer for teams that (want to) work with ISO 9001 or IATF 16949?

Symbol offers comprehensive training for teams working with ISO 9001 and IATF 16949, including courses on Core Tools and auditor training. These trainings focus on implementing and maintaining effective quality management systems.

Can Symbol help maintain ISO 9001/IATF 16949 certification after obtaining it?

Yes, Symbol not only provides assistance in achieving certification, but can also provide support in maintaining and continuously improving the quality management system to ensure it continues to meet standards.

Ready for quality and for certification?

Symbol supports the development of quality management systems according to ISO9001 and IATF 16949. Does your organization need help getting ready for certification or does it need employees to take the necessary training? Then contact us today and request a consultation!