A3 thinking, what is it? More than just the paper size!

This white paper seems to be about a method or technique. This is partly true. Of course it is a method, with a format and certain rules. But it is much more than that. It is about development. Development of the organization by developing employees.

An organization that is serious about A3 thinking is first and foremost developing people on how to apply A3 thinking effectively in order to solve problems.

A3 thinking, what is it?

A3 thinking is simple and logical to begin with. This makes the methodology applicable at all levels of your organization, regardless of the educational level of the employees. The common thread in the method is to develop people into continuous improvers. The method originated within Toyota, where Taichi Ohno was one of the driving forces behind its development and further refinement. Ohno is also the one who pointed out that A3 thinking is a means and not an end. The ultimate goal is continuous improvement. A3 thinking facilitates the organization and its people to achieve this.

Continuous improvement means a little better every day. Every employee is constantly looking for improvement opportunities. What could be better? What is holding us back? Can we challenge our process even more?

Another important feature of A3 thinking is the reporting method. This is where the A3 paper size comes in. If you have limited space, you will need to formulate concisely. So you can only communicate the essence of your subject. And that is one of the key points of A3 thinking; summarize well and formulate concretely.

A3 Thinking: From an intrinsic motivation, employees want to continuously improve processes based on the correct and current data.

A3 Doing: A3 thinking leads to appropriate application of methods, techniques and the reporting format and ultimately to better problem solving.

The shop floor is the place to find A3 teams. The closer to the process the solution is sought, the more effective. Those directly involved are also really directly involved and part of the team.

There are three types of A3 methods: The problem-solving A3, the proposal A3 and the A3 status report as a summary of one of the first two. This white paper focuses on the problem-solving A3, the most commonly used.

A3 and PDCA

PDCA (Plan Do Check Act) is the backbone of A3 thinking. A tool we need to make use of. Taichi Ohno had the following opinion about this:

- Tools are on the surface, not at the heart of continuous improvement.

- They are the visible part of continuous improvement.

- They enforce proper behavior.

- They can be used until they are obsolete.

The latter is an apparent contradiction. What he means here is: we will strive for perfection, but not achieve it. Hence, we must guard against wrong behavior. We do this by strictly adhering to proven methods and techniques. Until it is ingrained in our DNA.

When are we successful? When we start to recognize problems automatically, solve the problem completely and also be sure that the problem is solved.

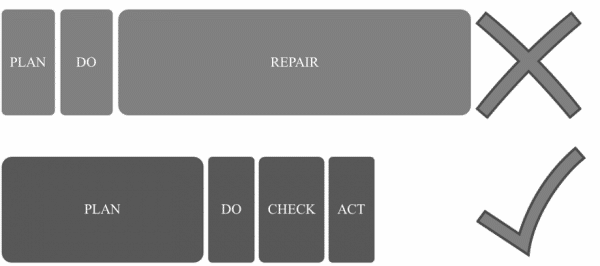

The PDCA circle is a visualization of the steps within A3 thinking. Remarkably, much time is taken to prepare the change (improvement) correctly, which is then successfully rolled out in a short period of time. As a result, the overall process will be shorter and the results will be better and sustainable.

PDCA Roadmap

An important part within A3 thinking is proper problem definition. In essence, this is the description of a situation that deviates from the desired situation (the “gap”). Moreover, singular, specific and relevant:

- Single

- Specifically

- Relevant

Finally, of course, a problem description never includes a solution!

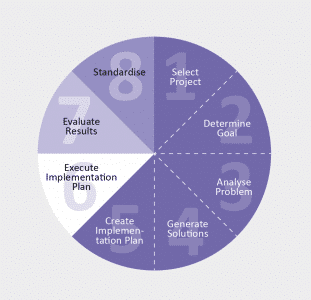

- Identify possible problems, pick one and select a team.

- Set the improvement goal through SMART criteria and make time available.

- Analyze the problem, identify possible causes, involve the environment (internal customer).

- Think of possible solutions and make a good choice from these.

- Develop an implementation plan, present the proposals to management, and seek approval to implement the plans.

- Implement the implementation plan.

- Measure the effect of the solution. In doing so, use the previous registrations.

- Standardize improved practices.

7 elements

Within A3 thinking, 7 elements are applied continuously and in parallel. So this is not a seven-step plan but a seven prerequisite. In other words, a way of thinking to develop people into ever better problem solvers.

1: Logical thought process

- Discipline in PDCA and standardized method.

- Root cause oriented.

2: Objectivity

- Use dates to correctly describe the problem.

- Test for false assumptions and false conclusions.

3: Results and process

- 50/50; both are equally important to sustained improvement.

- So: achieve results with an excellent improvement process.

4: Synthesis, distillation and visualization

- A3 reports are concise.

- Show key data from all analyses.

5: Alignment

- Make sure all involved agree on cause of the problem and countermeasures.

6: Coherent and standardized approach

- There is consistency between the problem and the ultimate goal of the organization. Furthermore, countermeasures, for example, are always the result of a Root Cause Analysis.

- The standardized approach allows A3-s to be understood by everyone in the organization.

7: System focus

- Understand how countermeasures affect (positively) the entire process.

- Countermeasures should not create new problems.

Practical application

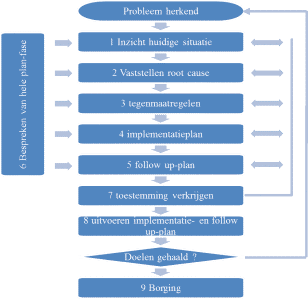

Now how can the above theory be applied in practice? A roadmap is shown in the following model:

The model clearly identifies the comprehensive planning phase of the PDCA approach. Steps 1 through 7 fall within the plan phase where there is constant communication between all involved. At the end of the plan phase, everyone is clear:

- What the problem is

- What causes

- How we are going to fight these

- How we will implement this

- How we are going to verify the results

- What the situation will be like after implementation of the countermeasures.

This leads to extremely fast implementation of improvements. If everything is well prepared in the plan phase, it will be seen after implementation that the goals have been met. In that case, the final step is to secure the new, improved situation. If not, the roadmap is run again to achieve the goal in the second instance.

Symbol method

Within A3 thinking, it is not only about solving problems but also about developing people into ever better problem solvers. This fits seamlessly with Symbol’s approach. We train people in various methods and techniques to a theoretical and practical level sufficient to independently put what they have learned into practice within their own organizations.

In the area of A3 thinking, Symbol has established a balanced training program. Within this, theory is trained in two days using one or more practical cases. Optionally, fully customized in-company training can be provided where employees are challenged to bring their own real-life cases to be discussed in the training group. Please feel free to contact us to discuss the possibilities.