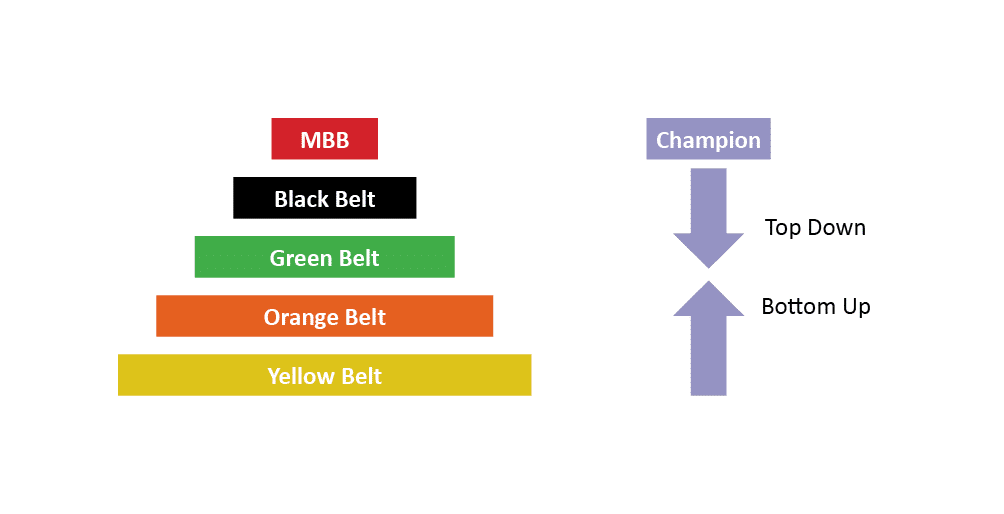

Lean Six Sigma organizational structure

Within a Lean Six Sigma organization, one or more (Master) Black Belts will be responsible for training and mentoring the organization. Lean Six Sigma improvement projects are conducted by Green and Black Belts. The Yellow Belts and Orange Belts support the projects as team members in larger projects or carry out smaller (Kaizen) projects independently. Managers, in their role of “Champion,” are the principals of the projects. They facilitate and provide the resources needed to implement the projects.

Lean Six Sigma offers not only powerful statistical techniques but also a structured approach to implementing an improvement project. This approach is called DMAIC, which stands for Define-Measure-Analyze-Improve-Control. Although the DMAIC roadmap has its origins in Six Sigma, it can also be used for Lean projects.